In the sheet metal processing industry, the hydraulic press machine is indispensable. People can see it everywhere in this field. But do you know its working principle?

First, let’s learn a little about what is a hydraulic press

A hydraulic press is a mechanical device that uses liquid (usually oil) as a transmission medium to transmit force and energy in a closed system to achieve work. Hydraulic presses use the high pressure transmitted by a liquid in a pipeline to generate large forces and movements. They are often used in processes and applications such as machining, forming, stamping, bending, and pressing.

Hydraulic presses have many advantages, including high power density, high efficiency, high reliability, strong controllability, and suitability for high-load and high-pressure applications. Hydraulic presses are widely used in industry, construction, aerospace, automobiles, ships, mining, metallurgy, and other fields. Standard hydraulic presses include hydraulic presses, hydraulic punches, hydraulic shears, hydraulic bending machines, etc.

How a hydraulic press works

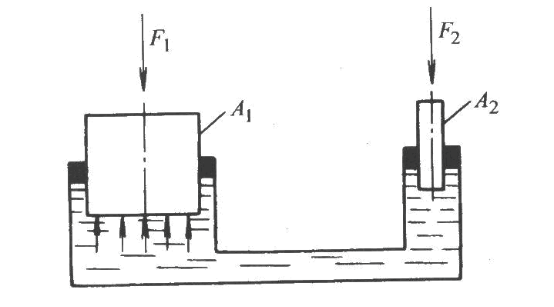

The areas of the large and small plungers are 2 and 1 respectively, and the effect forces on the plungers are 2 and 1 respectively. According to Pascal’s principle, the pressure of a closed liquid is equal everywhere, that is, 2/2=1/1=p; 2=1(2/1).

It shows that the hydraulic gain effect is the same as the mechanical gain, the force is increased, but the power is not increased, so the movement interval of the large plunger is 1/2 times the movement interval of the small plunger.

The basic principle is that the oil pump delivers the hydraulic oil to the integrated cartridge valve block, uses the incompressibility of the liquid and the properties of the fluid to transmit the force, and distributes the hydraulic oil to the upper or lower chamber of the cylinder through each check valve and overflow valve, through the liquid pump to raise the liquid pressure to a certain level, under the effect of high-pressure oil, the piston in the hydraulic cylinder is driven by hydraulic pressure, so as to realize the transmission of force and the completion of work. Liquids obey Pascal’s law when transmitting pressure in a closed container.

The hydraulic transmission system of the four-column hydraulic press is composed of power organization, control organization, executive organization, auxiliary organization, and working medium. The power organization usually uses an oil pump as the power organization, usually a positive displacement oil pump.

In order to meet the requirements of the movement speed of the executive organization, one oil pump or more oil pumps are selected. Gear pump for low pressure (oil pressure less than 2.5MP); vane pump for medium pressure (oil pressure less than 6.3MP); plunger pump for high pressure (oil pressure less than 32.0MP).

The above content explains how the hydraulic press is stressed during operation, it’s basically according to Pascal’s law. The hydraulic press has been invented over 200 years, it’s been improved uncounted times, and the technology of the huge machine has already very matured. Its work range explored by pioneers is endless. So, I think it’s not bad to learn more about this machine.

The following is the general working principle of a hydraulic press:

- Liquid supply:

Hydraulic machines usually use liquid (usually oil) as the working medium. Fluid is usually supplied to the cylinder by a fluid pump through lines.

- Hydraulic cylinder:

The hydraulic cylinder is the key component of the hydraulic machine, usually consisting of a closed cylinder with a piston. The liquid enters the hydraulic cylinder through the pipeline, and the pressure is generated in the hydraulic cylinder so that the piston is subjected to force and moves.

- Transmission of hydraulic pressure:

The pressure generated by the liquid in the hydraulic cylinder is transmitted to the working parts (such as molds, workpieces, etc.) through the piston, to realize the transmission of force. The incompressibility of the liquid ensures that the pressure generated in the hydraulic cylinder can be accurately transmitted to the working parts.

- Control system:

The hydraulic press is usually equipped with a control system, which is used to control the flow and pressure of the liquid and to realize the operation and control of the hydraulic press. The control system usually includes hydraulic valves, control panels, sensors, and other components, which are used to control the start and stop of hydraulic pumps, the movement speed of hydraulic cylinders, and the magnitude of force.

Through reasonable hydraulic system design and control, hydraulic presses can generate large forces and movements and are widely used in processes and applications such as processing, forming, stamping, bending, and pressing in various industrial and manufacturing fields.

According to the above content, the explanation looks very complicated, but it is not that complicated when operating. If you are interested, you can see my last blog.

The main tips are to be careful to operate, easy to have work done!