The application of hydraulic systems in business is just developing for over a hundred years, but the application of power of wind and water is already over 5000 years.

A long time ago, there was a record of using the power of wind and water flow to make some kind of “mechanism” work instead of human beings. About 5,000 years ago, there were ships driven by wind, and 2,000 years ago, waterwheels were operated by water.

But this technology is developing very fast for over a hundred years. This technology has already become an indispensable part of the metal processing-related industry.

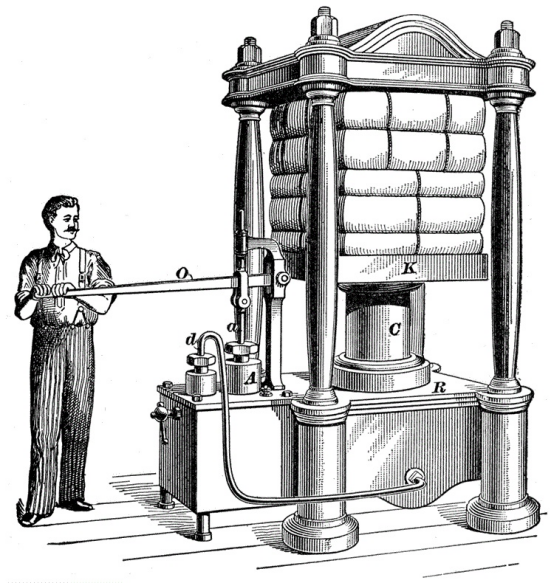

What is hydraulic press?

Hydraulic pressure can be used as a power transmission method to become a hydraulic transmission. Hydraulic pressure can also be used as a control method, known as hydraulic control.

The hydraulic transmission uses liquid as the working medium and uses the pressure energy of the liquid to transmit power.

The most important principle of the hydraulic press is Pascal’s principle.

The emergence of Pascal’s principle

Pascal’s principle was proposed by Blaise Pasca (1623~1662, France) in 1654 when he introduced the “Principles of Hydraulic Presses” in “Theory of Fluid Balance” written at the age of 31. He verified the balance of air pressure and mercury column, A special case of the fluid symmetry problem.

When he introduced the principle of the hydraulic press in “Theory of Fluid Balance”, he wrote: Fill a closed container with water and open two openings. The area of one mouth is 100 times the area of the other mouth. Piston seals on the two port plugs respectively. In this way, one person can press the small piston as much as 100 people can press the big piston.

This is what is now called “Pascal’s principle”.

The first appearance of the hydraulic mechanism

Pascal’s principle was proposed in the middle of the 17th century. However, it took nearly 200 years for the hydraulic mechanism technology to mature and its price can be acceptable to the public.

In 1882, there was a record of the use of hydraulic pressure in the reciprocating motion of a gantry bed. This is related to the widespread adoption of Henry’s acid converter steelmaking method in the 1860s.

At that time, the originally expensive steel can be put into mass production at a very low cost by using the acid converter method. It is necessary to use high-strength steel to manufacture annular pressure fluid containers, so it can be said that steel can be put into mass production at a very low price and has a close relationship with hydraulic machinery.

By 1920 hydraulic pumps had developed to a level where a reliable source of pressure could be easily obtained. Since then, not only simple reciprocating motion can be performed by using the hydraulic mechanism. It can also freely adjust the speed, reversing time, etc., and its application range is gradually expanded to grinding machines, broaching machines, and drilling machines.

From “water pressure” to “hydraulic pressure”

“Hydraulic pressure” and “water pressure” have a deep relationship. Water is the liquid that exists in nature in the form that is most accessible to us. When performing certain operations with liquids, water comes to mind, and there is no more readily available and less expensive liquid.

Replacing water with hydraulic pressure was only 100 years ago. After the publication of “Principles of Hydraulic Press” in 1654, for about 230 or 240 years, “hydraulic pressure” was used instead of “water pressure”.

Needless to say, “water pressure” is used even now, but compared with hydraulic pressure, it is only used in a certain field. And the number is small. For example: for the red-hot iron block molding Forging machinery. There is a risk of fire when oil is used, so water pressure is used.

From the beginning of the 19th century to the second half, various machine tools were developed, and a fairly perfect water pressure machine was also produced. However, there are restrictions on water use, problems such as rust and corrosion, and poor lubricity. And the use temperature must be limited to 0-100 ℃ and so on.

These constraints are nerve-wracking. If the construction machinery that is often used outdoors uses a water pressure machine, it will freeze and cannot operate in severe winter, and it must be replenished frequently due to evaporation in midsummer.

From the beginning of the 19th century to the end of the 19th century, with the simplification of the production process of high-strength steel, commonly used equipment was further popularized, and it was used for precision machining machine tools.

Its power components include gasoline engines (internal combustion engines), diesel engines (internal combustion engines), and electric motors. After that, there was a method of refining lubricating oil with petroleum, which suddenly transitioned from “water pressure” to “hydraulic pressure”.

Hydraulic transmission began to develop rapidly

The rapid growth stage of hydraulic transmission was in the First and second world wars. During the First World War, hydraulic components officially entered professional industrial production. ) made extraordinary contributions. In 1925, Vickers invented the pressure-balanced vane pump, which laid a solid foundation for the gradual establishment of modern hydraulic transmission.

During the Second World War, hydraulic transmission technology was widely used in the military. Until the 1960s, a large wave of new technologies was launched one after another, including atomic energy technology, space technology, and information technology. These technologies made hydraulic transmission go further.

Equipped with automation technologies such as hydraulic control and hydraulic testing, including CNC engineering machinery, CNC machining centers, and metallurgical automation equipment.