Trolleys are indispensable tools in modern logistics and construction industries, and employing hydraulic technology in their manufacturing process can offer numerous benefits. In this article, we’ll delve into the key steps involved in crafting trolleys with hydraulic technology and the corresponding advantages.

Key Steps in Manufacturing Trolleys

1. Design Planning

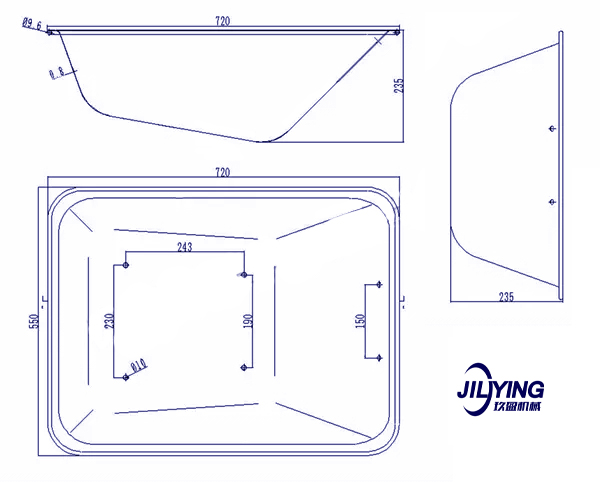

The process of crafting trolleys begins with design planning. This entails determining the dimensions, structure, and load-bearing capacity of the trolley, and creating detailed design blueprints according to requirements.

2. Material Preparation

Prior to manufacturing trolleys, the necessary materials need to be prepared, including metal pipes, steel plates, bolts, etc. These materials will be used to fabricate the main body structure, handles, and connecting components of the trolley.

3. Hydraulic System Design and Fabrication

The hydraulic system is a crucial component in trolley manufacturing, providing power and control for lifting and tilting functions. Typically consisting of hydraulic cylinders, pumps, control valves, and reservoirs, the hydraulic system is designed and fabricated based on the trolley’s design requirements.

4. Assembly and Testing

Once all components and systems are fabricated, the assembly and testing phase can commence. This involves assembling the main structure, handles, wheels, and hydraulic system components, followed by testing to ensure the trolley operates smoothly and reliably.

Advantages of Hydraulic Technology in Trolley Manufacturing

1. Enhanced Load-Bearing Capacity

Trolleys manufactured using hydraulic technology typically boast greater load-bearing capacity, enabling easy transportation of large and heavy items, thus improving work efficiency.

2. Flexible Lifting and Tilting Functions

Hydraulic systems enable trolleys to have flexible lifting and tilting functions, making them suitable for various height and tilt-angle requirements in work environments, thereby enhancing operational convenience and safety.

3. Smooth Operation

Hydraulic systems provide smooth power transmission, reducing vibrations and noise during trolley operation, and creating a more comfortable and stable work environment.

4. Efficient Energy Consumption Control

Hydraulic systems often feature efficient energy consumption control capabilities, allowing real-time adjustment of hydraulic pressure and flow rates based on actual workload, thus reducing energy consumption and improving operational efficiency.

Conclusion

Employing hydraulic technology in trolley manufacturing offers significant advantages for the logistics and construction industries, including enhanced load-bearing capacity, flexible functions, smooth operation, and efficient energy consumption control. By carefully designing and fabricating hydraulic systems, trolleys can exhibit superior performance and reliability, ultimately increasing work efficiency and reducing operational costs.

If you’re seeking professional services for crafting trolleys using hydraulic technology, feel free to contact us. We’re committed to providing customized solutions and support tailored to your needs!